Expert’s Rating

Pros

- 320 x 320 x 400mm build volume

- Relatively affordable

- Fast

Cons

- Takes up a lot of space

- Filament reel holder position could be better

- Cloud printing doesn’t work properly

Our Verdict

The Kobra 2 Plus is a good-value 3D printer for those that need a large build volume for big models, and don’t want to wait long for them to be printed. Quality is decent with the right filament, too. Problems with cloud printing and noisy fans took the shine off, though.

Price When Reviewed

$449

Best Prices Today: Anycubic Kobra 2 Plus

$549.99

Having previously reviewed Anycubic’s Vyper and being impressed with its reliability and overall quality, I was keen to see how far things had progressed with the Kobra 2 series.

Unlike coreXY printers such as the Bambu P1S and Creality K1, the Kobra 2 printers stick with the traditional “bed-slinger” design. This is where the print surface moves backwards and forwards and the print head moves side to side (and upwards).

The coreXY motion system lends itself to faster printing but manufacturers have figured out how to increase the print speed of bed-slingers. The Kobra 2 Plus, then, claims to be 10X faster than traditional models and can print a 3Dbenchy in 17 minutes.

There are four other models in the range: the Kobra 2 Neo, Kobra 2, Kobra 2 Pro and Kobra 2 Max. The Neo is the budget model which prints at a maximum of 250mm per second, the Kobra 2 at 300mm per second and the other three can – theoretically – go up to 500mm per second.

The main difference between them is build volume. The Kobra 2, Neo and Pro are all 220x220x250mm, the Plus is 320x320x400mm / 15.7×12.6×12.6 inches and the Max can print enormous models up to 420x420x500mm.

This review is focused on the Plus, which costs £449 / $449.

Features & Design

- Automatic levelling

- 4.3-inch touchscreen

- Direct-drive extruder

If you’re new to 3D printing you might think you need a bigger build volume that you really do. More often than not models are quite small, but then again, it depends on what exactly you want to print.

This type of 3D printer uses standard 1.75mm filament. PLA is the most common type of filament and it’s very easy to glue together using superglue, so it’s possible to print large models by splitting them up into smaller sections and printing them individually.

I asked Anycubic to send the Kobra 2 Plus because I wanted to find out if it had managed to create a bed-slinger that could print as quickly as a coreXY printer at a bigger-than-usual size.

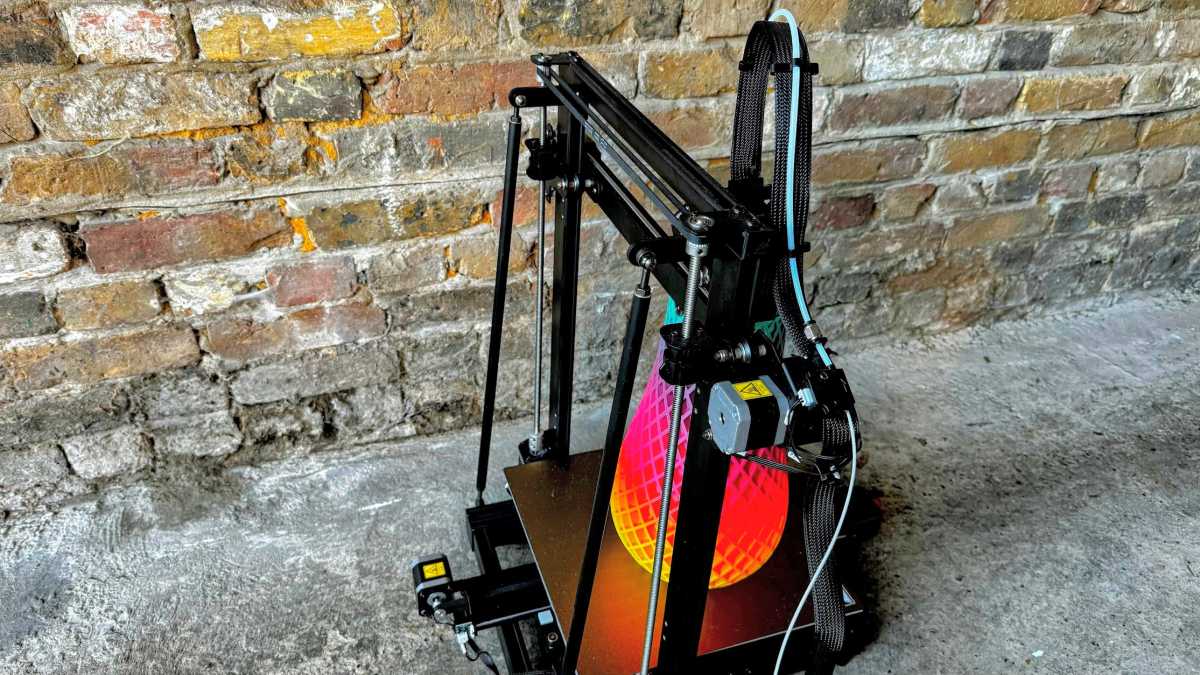

As the build volume increases, the harder it is to print accurately. That’s one reason why the Plus has supporting rods for the gantry and two z-axis motors (and therefore two leadscrews) to keep everything stable.

Jim Martin / Foundry

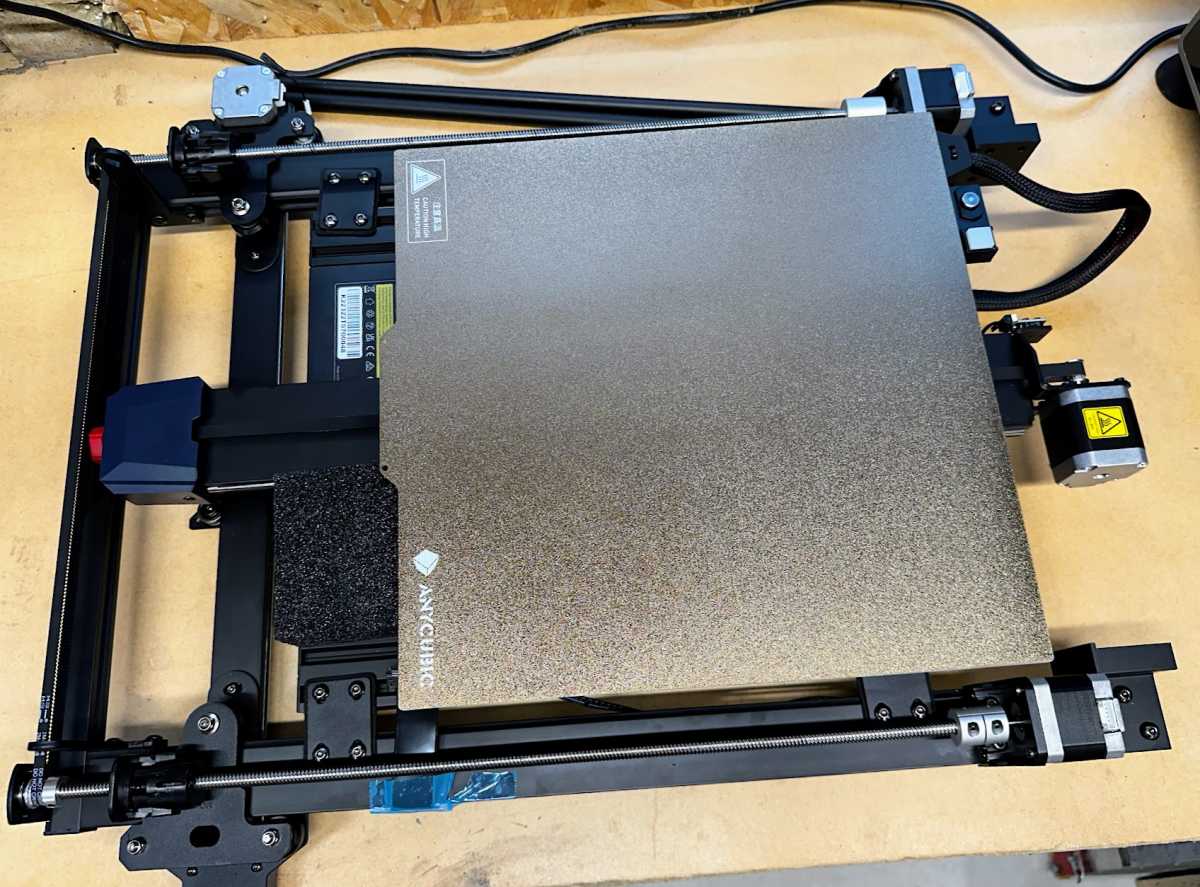

Like many other 3D printers, the Kobra 2 Plus has a heated bed with a magnetic and therefore removable textured steel plate. Once printing is finished, you simply lift off this plate and flex it to remove the model.

The filament – which isn’t supplied – sits on a reel off to the left and is fed through a run-out sensor and a reverse Bowden tube to the extruder that feeds it into the hotend.

This can heat up to 260°C, some 40°C off the 300°C some rivals offer, but it should be enough to handle PLA, ABS and PETG. Anycubic also lists the flexible TPU filament as one of the materials the Kobra 2 Plus can handle, but if you want to use that, you’ll need to set much slower print speeds – around 100mm per second.

The included nozzle isn’t hardened so you can’t print with abrasive filament such as carbon fibre PLA.

The bed goes up to 90°C, which is again lower than some printers. But again, it should be enough for most people.

Do note that as this is not an enclosed printer you might need to put it in a cabinet if you want to print with ABS or PETG which need a constant ambient temperature that’s higher than normal room temperature to avoid problems with warping. This isn’t an issue if you’re just printing with PLA though.

Setup

The printer arrives in two main pieces: the base and the gantry. These are fastened together with 16 screws for shipping, which is unusual, so removing them takes a little while before you can start actually assembling all the parts.

Jim Martin / Foundry

The instructions that come in the box are good, though, and it took me about 30 minutes before I could power it on for the first time.

When you do this, you’ll be walked through choosing your language, connecting to your Wi-Fi network, installing the Anycubic app on your phone – where you need to create an account and then scan the QR code to connect the printer to your account so you can monitor it from the app.

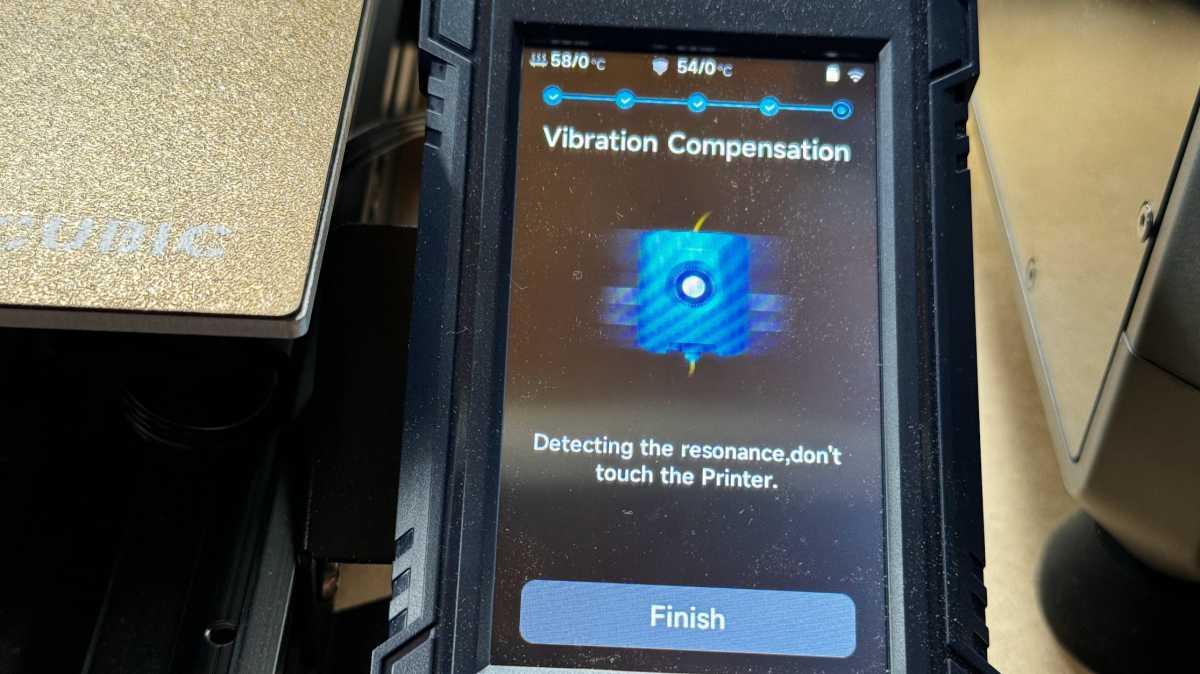

Jim Martin / Foundry

After that, it’ll run through a self-test process, automatic levelling, loading some filament, and finally vibration compensation (which should be re-run whenever you move the printer to a new location).

Jim Martin / Foundry

You can then print any of the models pre-loaded in the 8GB of on-board storage. But I’d advise against that as they all have a brim by default which is a pain to remove for the articulated dinosaur and even the bottle opener.

It is the simplest way to test that the basics are working, but pre-sliced files aren’t always the best demonstration of the quality you can get.

I didn’t like the placement of the filament spool holder because it’s right by the ribbon cable for the print head, and the two touch when the print head is low down. It also means you need a lot more desk space compared to if the holder were placed on top of the printer.

Jim Martin / Foundry

You’ll need a lot of space anyway: the Kobra 2 Plus measures 630x605x564mm / 24.8×23.8×22.2 inches (HWD) and needs much more depth that to allow for the full travel of the print bed – at least 700mm.

Performance

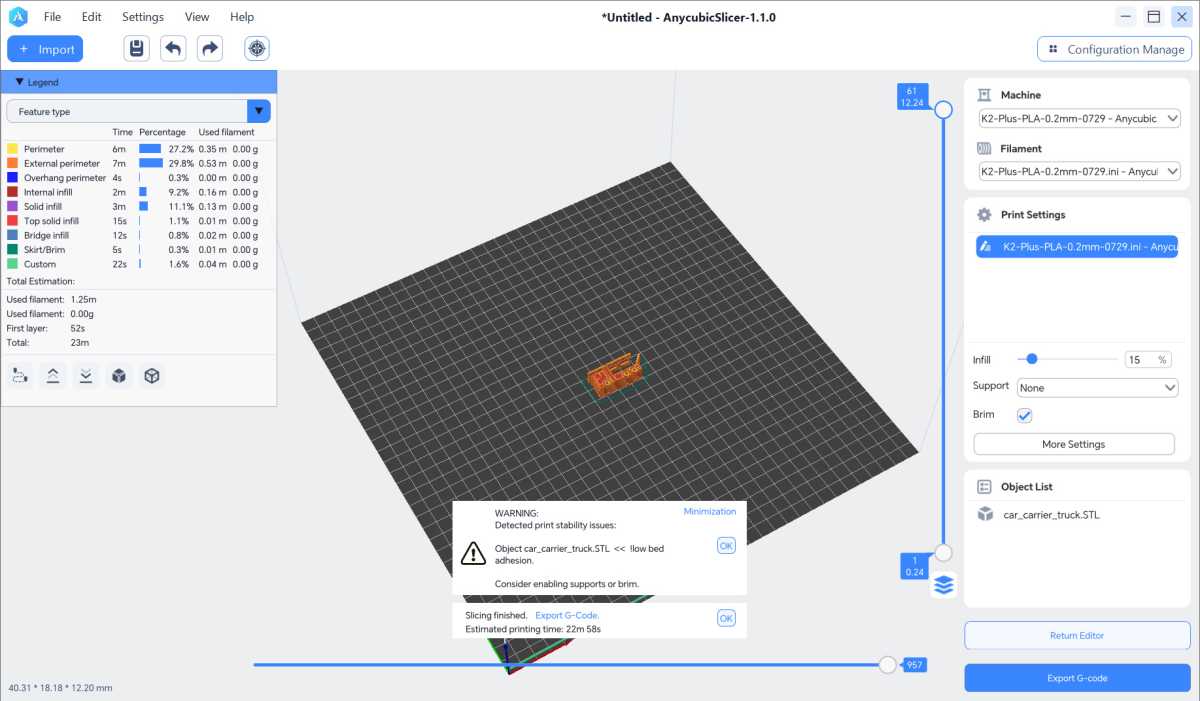

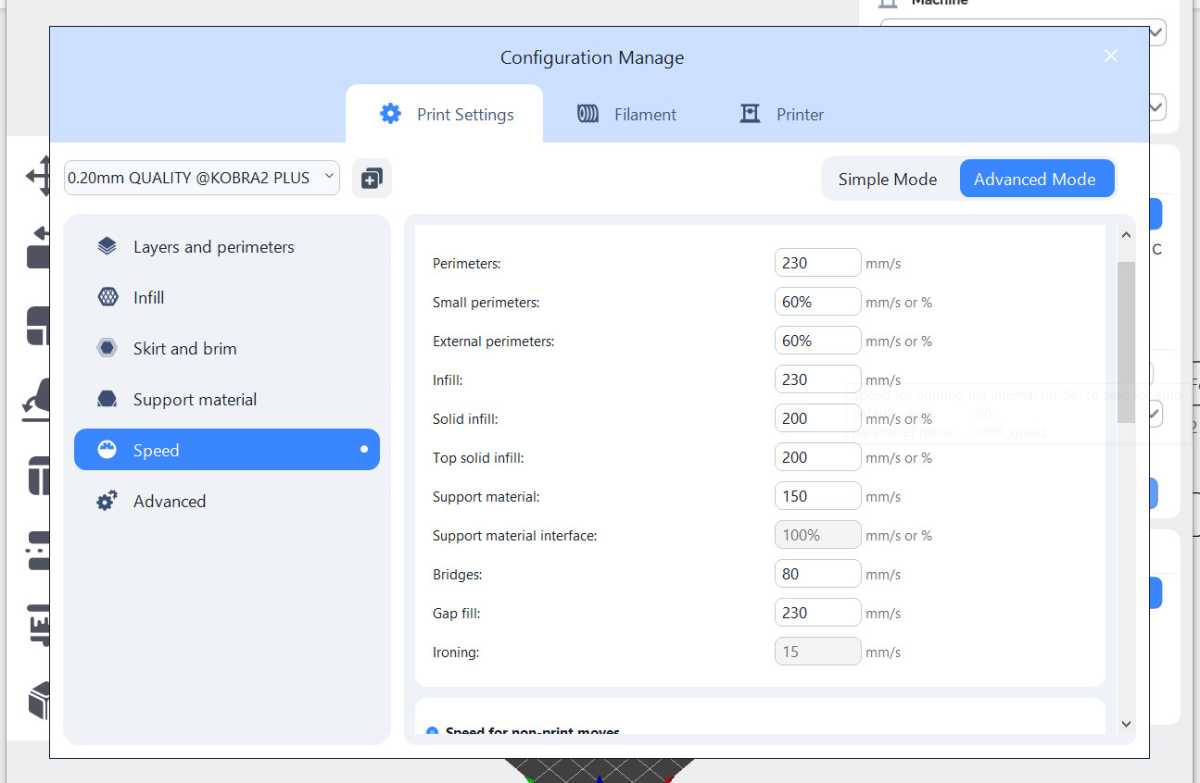

I printed my usual selection of test files, slicing them using Anycubic Slicer – the company’s clone of the popular open-source Prusa Slicer – and using the PLA profile supplied on the USB stick.

Get the right combination of filament and settings – and slicer software – and the Kobra 2 Plus is capable of decent quality

It’s strange that Anycubic doesn’t provide more profiles for other types of filament, and there isn’t even one to cater for non-high-speed filament.

Jim Martin / Foundry

As you can see below, the default speeds aren’t anywhere near the 500mm per second maximum claimed speed, nor are they even the 300mm per second average speed that’s advertised. However, there’s nothing to stop you increasing them from these presets.

Jim Martin / Foundry

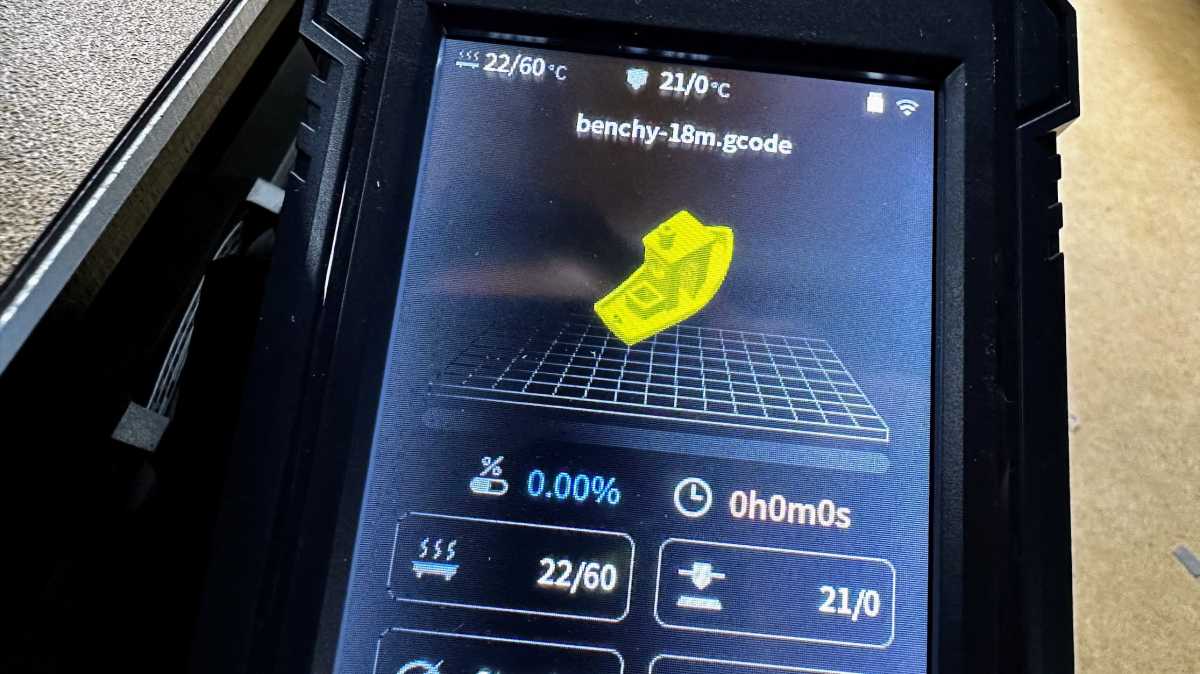

At these settings a 3DBenchy will print in just over 30 minutes. But the pre-sliced Benchy on the USB stick prints in under 20 minutes.

Jim Martin / Foundry

Using some high-speed grey filament that Anycubic sent for testing, print quality wasn’t the best at the default settings. You can see it’s not very clean at all on the side of the slug below. I tried various other prints and then swapped to some high-speed filament I had left over from testing the Creality K1 Max and prints were much better quality, suggesting Anycubic’s wasn’t as good. It certainly turned very brittle at the low temperatures in my garage of around 10°C.

Jim Martin / Foundry

Get the right combination of filament and settings – and slicer software – and the Kobra 2 Plus is capable of decent quality as this Benchy shows. It printed in around 30 minutes.

Jim Martin / Foundry

I like to test each printer’s tolerance with a few articulated models including this slug. At the default size, printers often end up fusing the segments together, which is exactly what the Kobra 2 Plus did.

A similar thing happened with some of the hinges on this infinite cube which also fused together. While a few of the hinges were simply a bit stiff, a couple wouldn’t budge and forcing them caused the plastic to break.

Jim Martin / Foundry

I thought it might be – again – old filament at fault, but I threw the reel into the Bambu P1S’s AMS and used the same 0.2mm layer height. No problems with fused hinges at all: the cube folded perfectly.

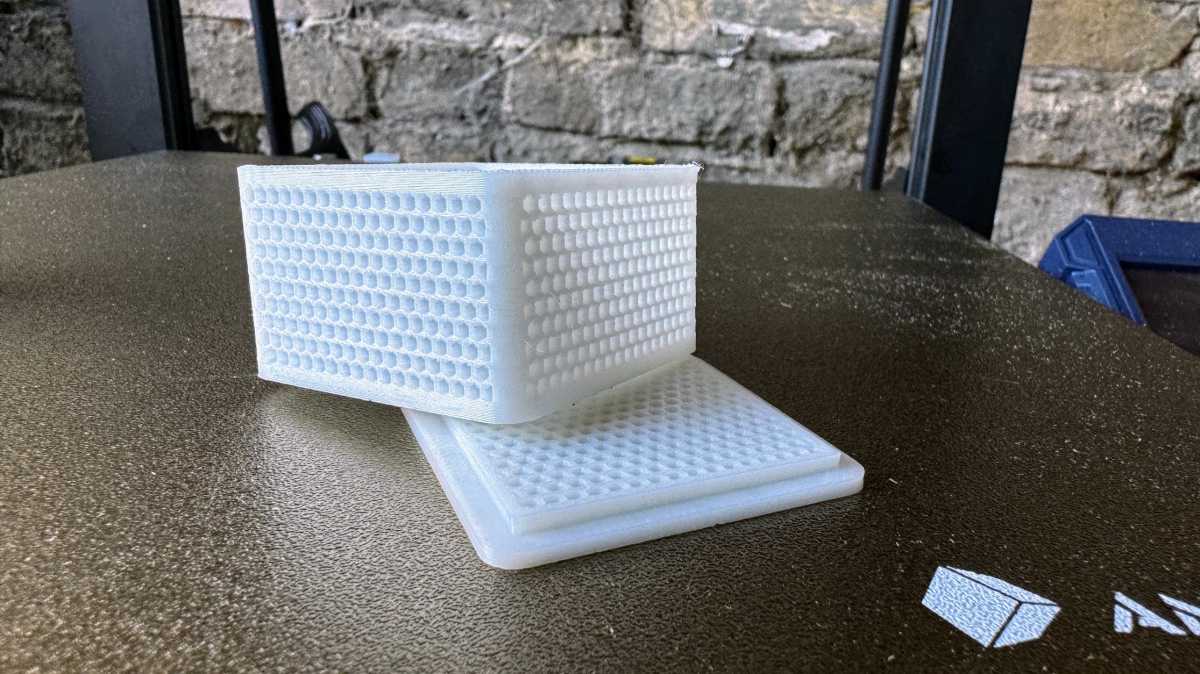

I then printed this tiny honeycomb box with a matching lid. Printing both parts at once proved too much for Anycubic Slicer which did warn me that there was a problem with the movement path which I ignored and ended up with a complete mess.

Jim Martin / Foundry

Printing them separately worked much better and demonstrated that the Kobra 2 Plus’s retraction is great: there was minimal stringing and the box looked great.

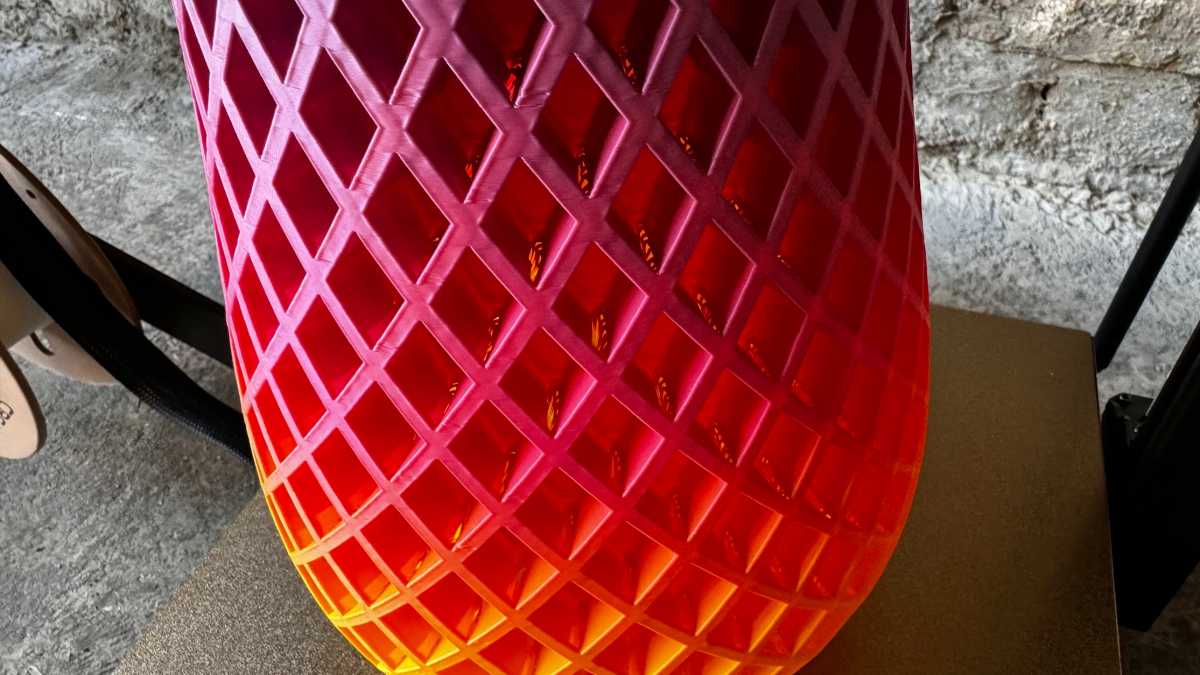

To test for any layer shift with large prints, I printed the double-spiral vase (shown in the photo at the top of this review) almost 400mm tall. I used some rainbow filament and ticked the spiralize setting in the slicer. It’s hard to say if the gaps at the bottom of each diamond are due to the filament not being specifically high-speed stuff, but the end result looks great.

Jim Martin / Foundry

It was also good that, despite a lot of “shaking” of the model as the print bed moved back and forth quickly, the vase stuck firm to the build plate, as did all the prints I tried. You may need use a glue stick if you want to print with ABS as you’ll almost certainly end up with some warping if you don’t.

In terms of noise, most of it comes from the powerful cooling fan. But the power supply also has fans and they were very noisy. I sent a video to Anycubic and asked if this was normal, and was told I’d need a new power supply, which would be provided under warranty. As of writing this review, that has not yet arrived.

App & cloud

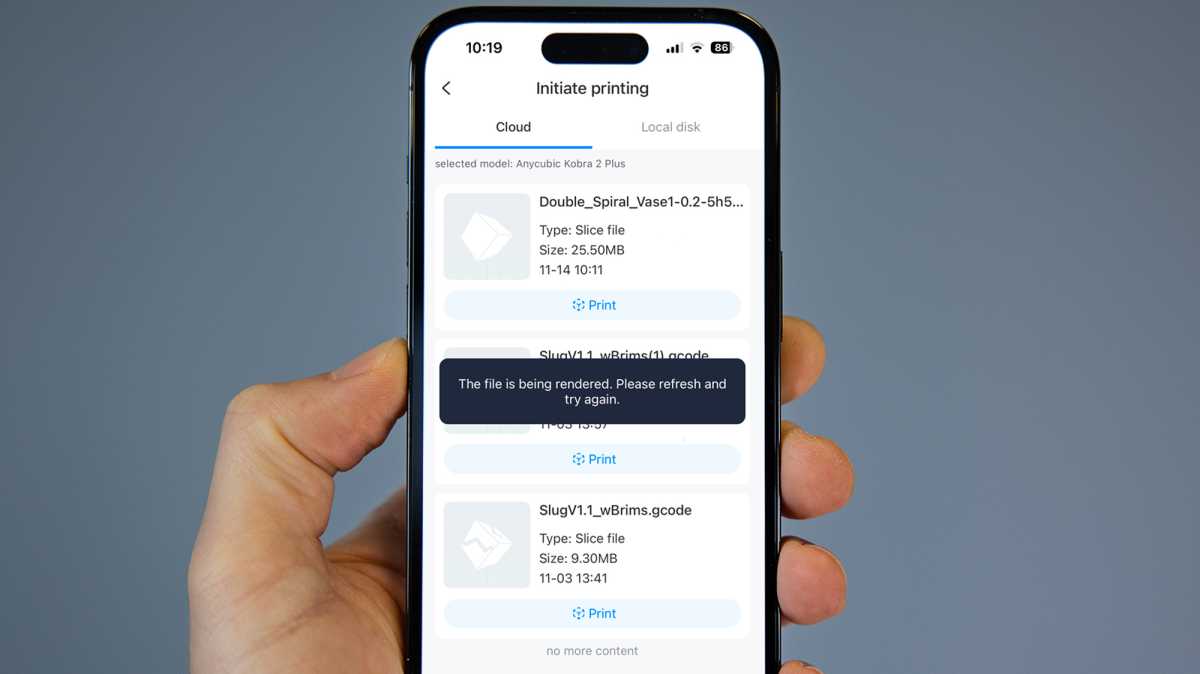

In the middle of testing, Anycubic released a significant firmware update which added support for cloud printing and monitoring. This turned out to be a huge palaver, partly because I ended up somehow installing the firmware for the Kobra 2 Max and Anycubic’s support then failing to instruct me to put the correct update file into an Update folder on a USB drive and instead saying the file needed to be in the root folder where the printer completely ignored it.

Jim Martin / Foundry

However, the update should have been worth it as it means you can use the Anycubic app to find, slice, print and monitor progress of that print. The reality was much less impressive.

Printing from the app proved impossible. After choosing a model to print, the app remained on the slicing screen indefinitely and only when trying to cancel it did it move onto the printing screen, but the printer itself never seemed to receive the print.

Jim Martin / Foundry

I tried the same thing from the Windows app: using the cloud service to remotely print a model sliced in the app. But yet again, despite assurances that the gcode had been sent to the printer, no printing ever began.

It’s worth saying that you can’t monitor print progress from the desktop app – only the mobile one. On mobile it works fine, and sends notifications when there’s a problem (such as the filament running out) and also when prints are complete.

Jim Martin / Foundry

The firmware supposedly added support for webcams as well, so I tried plugging in three different cameras into the USB port marked with a camera icon. At least one seemed to be working, as it’s LED turned on, but there was nowhere in the app to view the camera feed.

Jim Martin / Foundry

Ultimately, I ended up exporting gcode from the desktop app to a USB drive and plugging that into the Kobra 2 Plus, then monitoring progress from the mobile app.

A slick experience it was not.

Price & availability

The Kobra 2 Plus costs £449 / $449 from Anycubic’s website. For Black Friday, there’s a £50/$50 discount bringing it down to £399/$399.

That’s a tempting price for a printer with such a large print volume, fully automatic bed levelling and high print speeds.

If you’re thinking about saving money and see the original Kobra Plus on sale, just remember that its build volume is smaller (300x300x350mm) and it is much slower.

For alternatives, see our recommendations of what to buy in our best 3D printer roundup.

Should I buy the Anycubic Kobra 2 Plus?

Yes, if you’re looking for a 3D printer that can print larger-than-normal models quickly using PLA. With decent quality filament, it can do a…